Comprehensive Sensor Data for Wastewater Management

Multi-Sensor Inspection (MSI) for sewer pipes offers a comprehensive solution for accurately assessing sewer conditions, detecting defects, and providing condition grading to prioritize maintenance and repairs. Utilizing high-resolution CCTV, laser profiling, and sonar data, our service ensures efficient, cost-effective inspections with reduced disruption. Advanced analytics and automated reporting deliver actionable insights and regulatory-compliant documentation. Our robust and reliable equipment covers difficult-to-reach areas, ensuring complete pipe coverage.

View and download more information about this service:

Multi-Sensor Inspection: Comprehensive Sensor Data for Wastewater Management

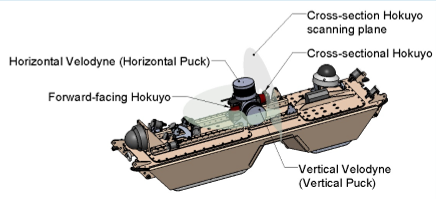

A comprehensive approach that combines CCTV, Sonar, Radar, and Lidar/Laser inspection techniques to provide a detailed condition assessment report. This method offers extensive data, including visual pipe assessment, debris levels, ovality, H2S corrosion, and 3D pipe images, and allows inspection in high flows without bypass.

• Insightful Data Collection: MSI captures extensive,

synchronized sensor data, offering a detailed

perspective on your system’s condition and delivering

crucial degradation metrics for effective rehabilitation

planning.

• Safer Method: Autonomous robotic technology

removes the requirement for human entry, enhancing

safety. Extended deployment periods minimize the

need for manhole access and decrease community

disturbances

• Cost Effective: Our tools function in any flow condition,

eliminating the need for bypass pumping. Reduced

deployment times decrease traffic control costs and

other additional expenses.

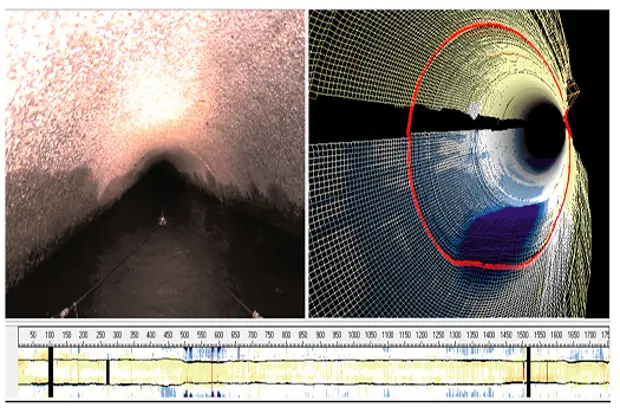

- Structural Defects and Damage: Obtain precise measurements for wall loss, ovality, deflection, and other degradation types. This data is crucial for rehabilitation planning and comparing future inspections.

- Sediment and Debris Quantification: Analyze capacity loss due to sediment and debris buildup and determine accurate cleaning costs based on debris volume.

- Remaining Useful Life (RUL) Assessment: Use digital twins and as-built drawings to evaluate every bend and curve of your assets. Accurate dimensions and modeling assist in determining replacement and rehabilitation costs and the RUL of your infrastructure.